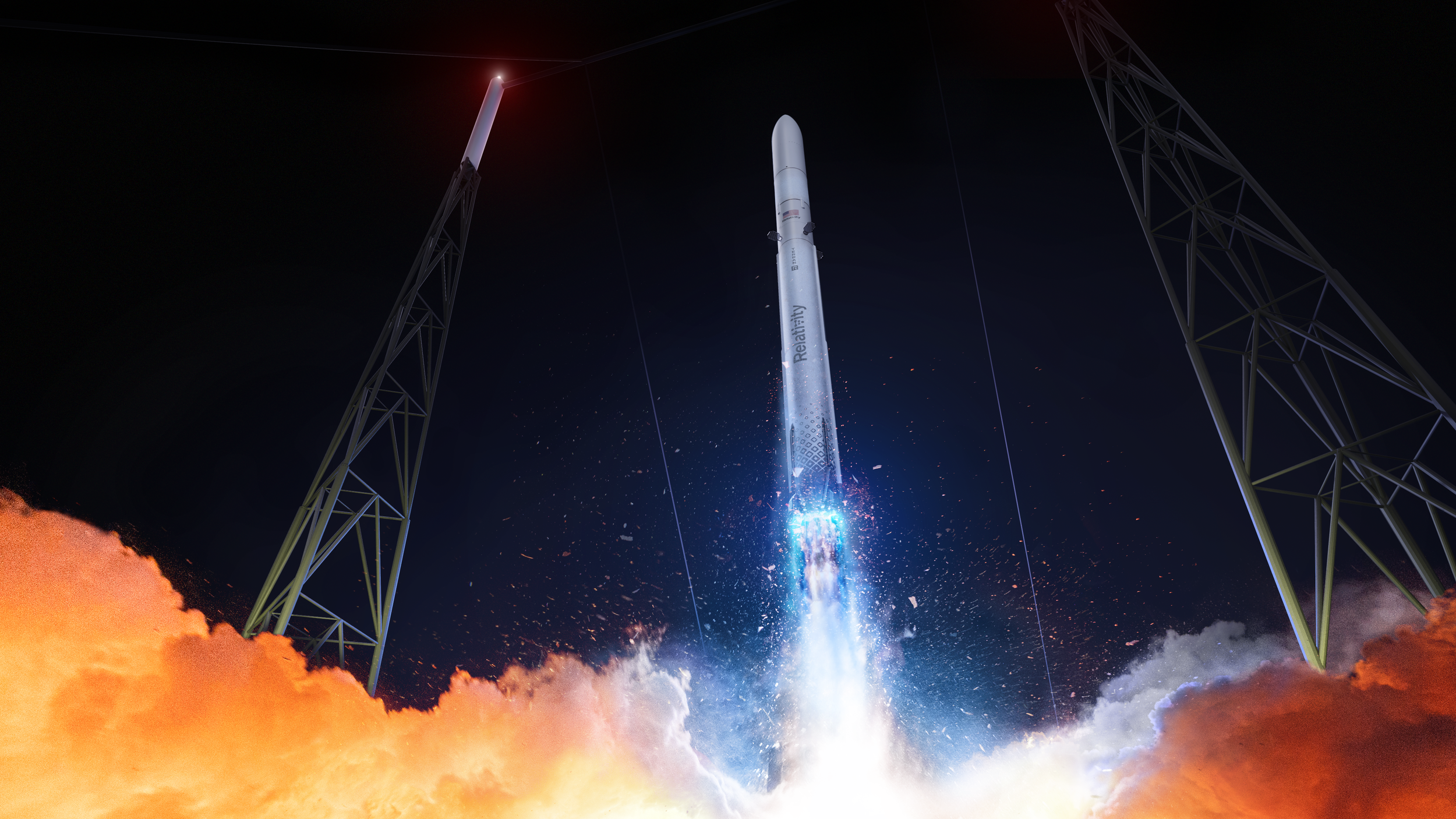

Terran R is a two-stage, reusable rocket built for today's satellites and tomorrow's breakthroughs. Perfectly sized to serve the Low Earth Orbit (LEO) constellation market, Terran R will make access to space more reliable and routine. Beyond LEO, we aim to empower science, exploration, and innovation across new frontiers.

Terran R Architecture

height of Terran R

diameter & payload fairing

total liftoff thrust

Strategic Economic Advantage

Built with cost effective, high strength aluminum alloys, Terran R is designed to deliver large payload capacity, competitive economics, and increased access to orbit. Terran R will launch from Launch Complex 16 at Cape Canaveral Space Force Station, Florida starting in late 2026.

to Low Earth Orbit (LEO), downrange landing

to Geosynchronous Transfer Orbit (GTO), downrange landing

to Low Earth Orbit (LEO), expendable configuration

Powering Terran R

Terran R is powered by 13 Aeon R engines on the first stage and 1 Aeon V vacuum engine on the second stage. Both use LOX-methane propellants and a high-pressure gas generator cycle, designed for performance, efficiency, and reliability.

total liftoff thrust

sea-level thrust of a single Aeon R engine

vacuum thrust of a single Aeon V engine

The Aeon R first stage engine went from design to qualification in just 14 months, validating the design that will power Terran R to space.

Trusted by Industry Leaders

Relativity has secured more than $3 billion in launch service agreements across government, commercial, and blue-chip telecommunications customers and partners.